We understand the shop floor pain points you face today:

- Aging workforce

- Understanding and documenting processes, either on paper of in people’s minds

- Turning collected production data into useful information to drive performance

- Integrating information technology (IT) and operational technology (OT)

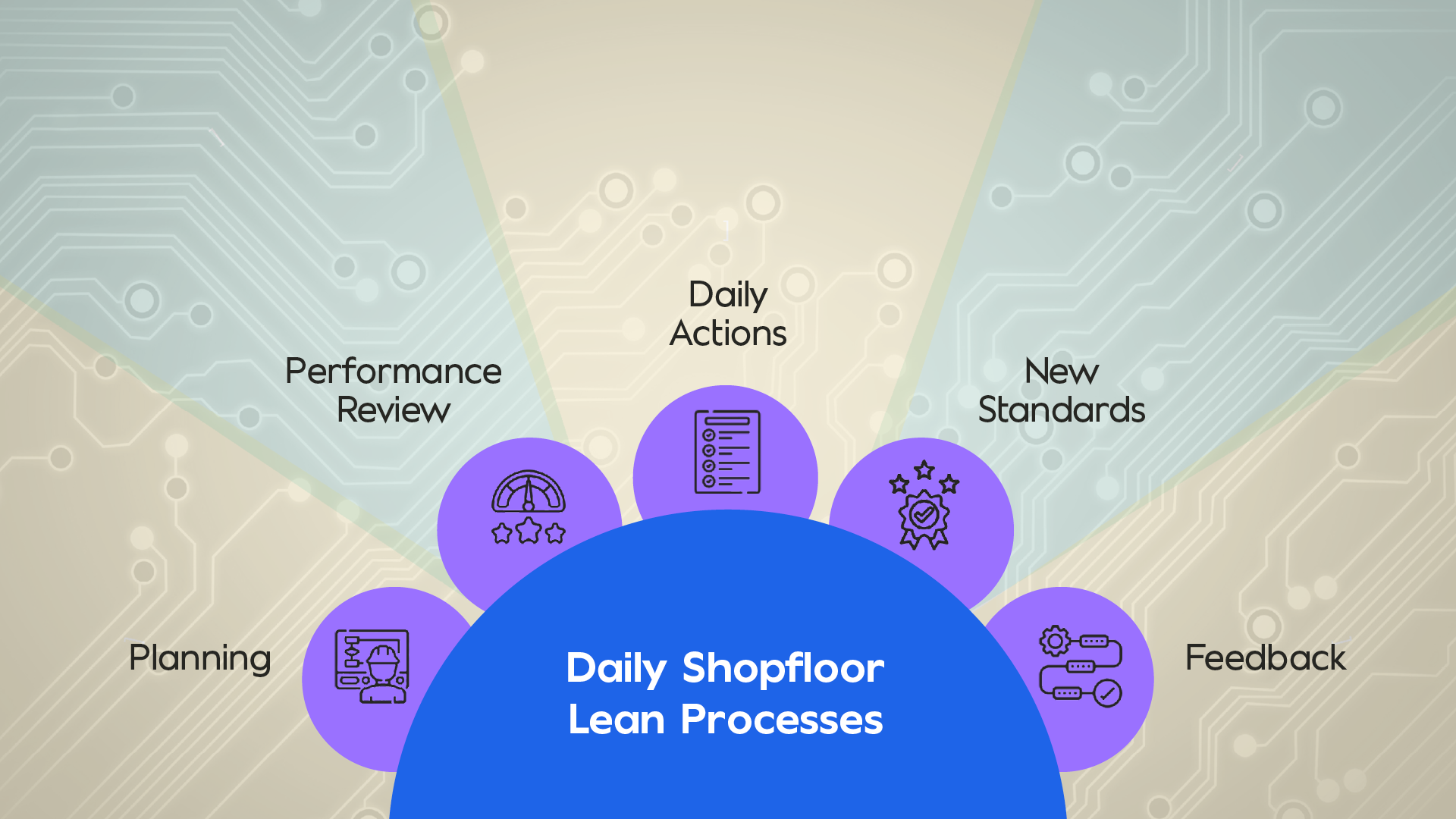

Real-time shop floor performance transparency

Structured data-driven problem solving

Utilising digital standards to capture and store knowledge

Continuous operator feedback and

input

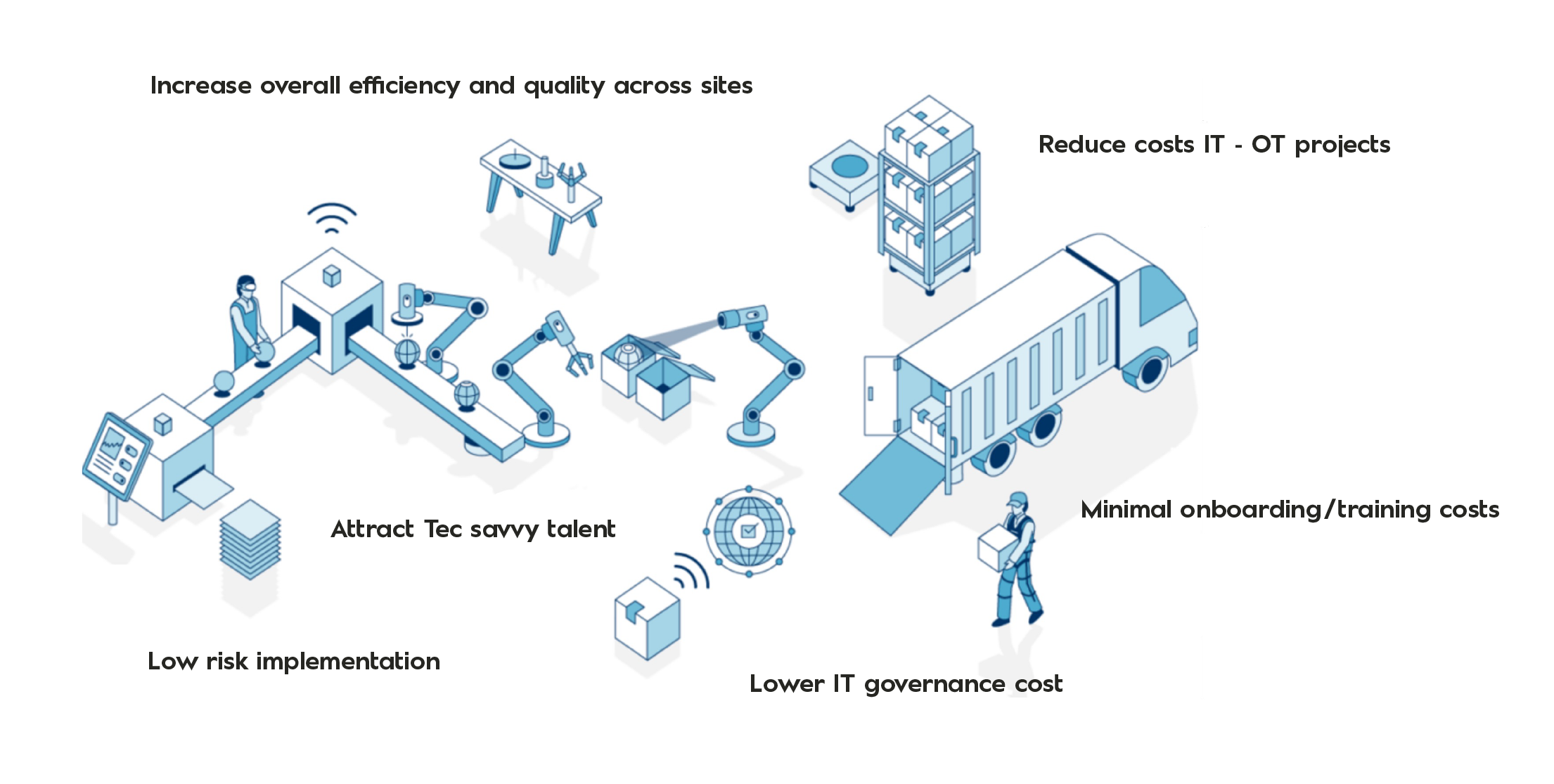

Delivering all these benefits when you digitalise your shopfloor

The benefits of Data-Driven Lean Manufacturing

Our lean shop floor digitalisation solution streamlines your processes, delivering real value.

- Reduced waste: identify and eliminate waste, such as rework, overproduction and inventory

- Improved quality: improve product quality by identifying and correcting defaults, early

- Increased productivity: automate tasks and improve your workflow

- Better decision making using real-time data and insights

Introducing the features of Data-Driven Lean Manufacturing

Planning with manning and daily boards

Helps you track and manage your workforce. It provides a comprehensive overview of who is working, who is qualified, and what certifications they have.

Daily huddle with real-time KPIs

Allows you to define rules to indicate performance levels, customise your KPIs and track and monitor the performance of your shopfloor operation.

Enhanced Gemba Walks

Provides you with digital platform for conducting Gemba walks efficiently. Allowing you to store notes, capture images, and document observations while on the shopfloor.

Data capture with dynamic checklists

Designed to empower your quality control processes, it allows you to create template root cause checklists to pin point areas that require more attention.

The full ecosystem

Discover the power of our people and the ecosystem of main partners

Our people

- Lean Six Sigma

- Toyota Operational Excellence

- IT in an OT environment

- Low code and full-stack software engineering

- Data extraction and insights

- Change management

Factorise

- Extensible solutions tailored to the shop floor

- Strong partnership to deliver data-driven operational excellence

- Example domains: production performance, issue tracking, and problem-solving, daily boards, and manufacturing intelligence

- Built-in OT connectivity

- Deployable on the edge

Mendix powered by Siemens

- The leading low-code platform

- Funded and led by the largest worldwide production software player

- Knowledge of IT and OT domains

We’re trusted by some of the biggest organisations to deliver their transformation needs

Get in touch

To book your demo or to find out how Valcon and Factorise can empower your shop floor digitalisiation, get in touch today.